Stainless Foundry News

How Inventory Stocking Programs Boost Manufacturer Efficiency and Responsiveness

Manufacturers can gain significant advantages when their foundry partner offers an inventory stocking program. Such programs provide a structured way to manage inventory, ensuring manufacturers are prepared for fluctuations in demand while optimizing production schedules and lead times.

Stainless Foundry & Engineering (SF&E) offers inventory stocking programs for finished and ready-for-machining parts to its manufacturing partners.…

Read Entire ArticleAdapt and Adopt: The Story of Stainless Foundry & Engineering

Throughout its history, Stainless Foundry & Engineering has remained dedicated to delivering high-quality castings and engineering solutions, adapting to industry advancements and adopting new processes to best suit customer needs. The following is a summary of where we’ve been and where we’re going.…

Read Entire ArticleCustomer-Centric Improvements Fuel Sustainable Growth

The number of industries relying on castings for pumps and valves continue to expand, and the volume of demand within each industry continues to grow. At the same time, the U.S. foundry landscape faces consolidation—making trusted partnerships more essential than ever. A customer-focused approach is ideal to solidify relationships, processes, quality, and longevity.

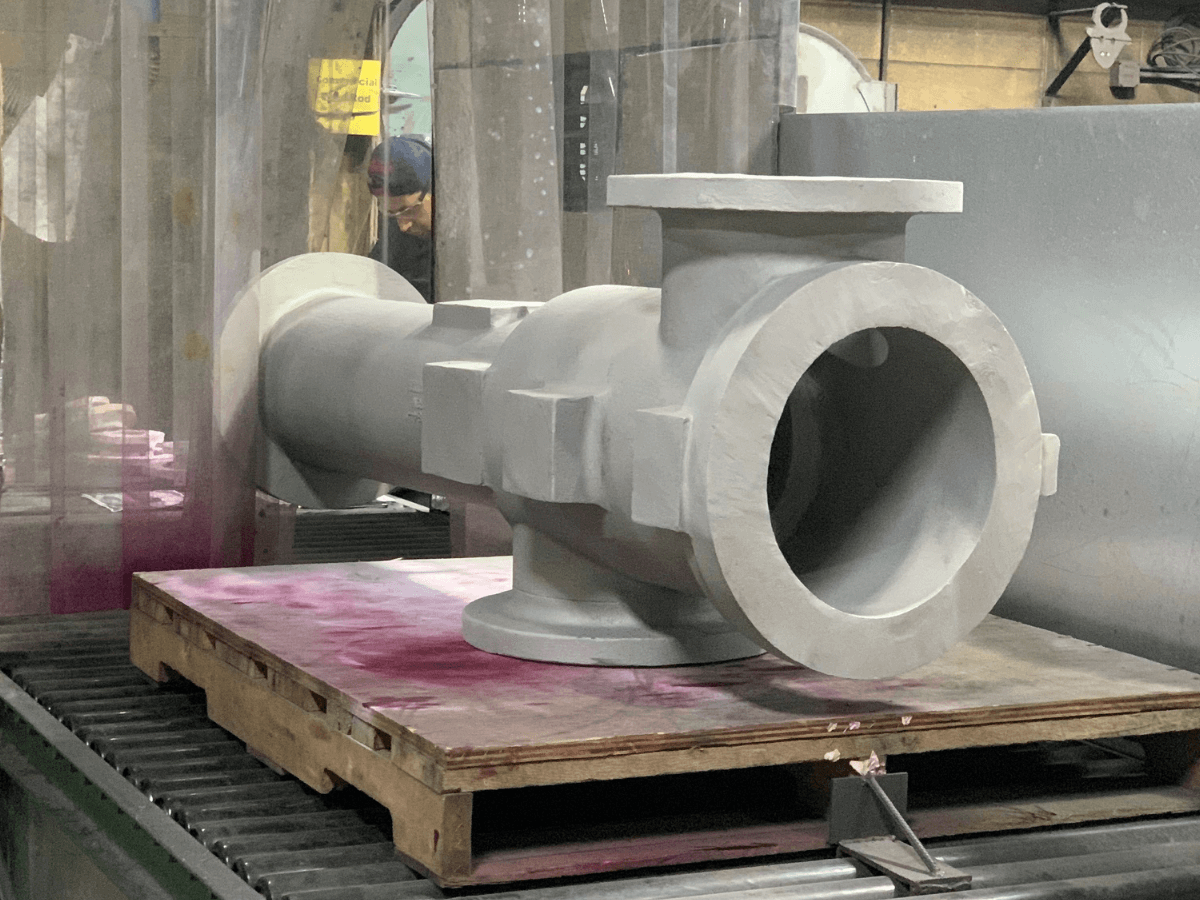

Read Entire ArticleThe Critical Work of Pressure Vessel Parts

Pressure vessels move media, including oil, compressed gas, hot water, chemicals, steam, and acid throughout a system. These systems are often essential to military, oil and gas, nuclear, food and beverage, or petrochemical operations, where it is critical that the pressure is retained.…

Read Entire ArticlePhoto Story: Current Trends in Machining

Machining puts the finishing touches on a casting – smoothing out rough edges to improve the surface area, removing excess material to meet tight tolerances, and adding shine. In recent years, advancements in Computer Numerical Control (CNC) technology, 5-axis machining and automated processes have been major drivers in foundry machining.…

Read Entire ArticleStainless Steel World Magazine Feature

Stainless Steel World Magazine highlighted the pressure standard usage and compliances required for high-spec casting production in the USA, UK, and EU. Read the full article for a deep dive into manufacturing high-specification castings with SF&E's Director of Quality and Technical Services, Michael Porfilio.

Read Entire ArticleCopper-Nickel Alloys for Military and Defense

The pumps and valves on aircraft carriers and submarines are not like those in manufacturing equipment and machinery. The first difference is that aircraft carriers and submarines require a variety of specialized systems to operate effectively and safely. The second difference is that most of their pumps and valves – which are constantly exposed to saltwater and varying temperatures – need to stay in service for the lifetime of the vessel, which can range from 25 to 30 years.…

Read Entire ArticleIn the Vital Metalcasting Industry, Reliable Foundry Partners are Key

Foundries are meeting increasing demand across sectors including automotive, aerospace, construction, and energy, with technological advancements. Innovations in design, metallurgy, and production are helping to improve the quality and efficiency of cast products. OEMs need strong, reliable foundry partners with the experience and capabilities required to step up to a challenge. Here are four ways to know if the foundry you are considering is right for you.

Read Entire ArticleChemical Composition Solves Top Challenges for Food and Beverage Manufacturers

The food and beverage industry relies on precise control, planned maintenance, and optimization of processes.

Read Entire ArticleThe Sky’s the Limit for Stainless Steel Investment Casting

The more a foundry can expand its capabilities, the more an original equipment manufacturer (OEM) can push the envelope with part design. This is especially true with stainless steel investment casting.

Read Entire ArticleSupreme Cores Empowers SF&E to Do What It Does Best

Starting in 2023, SF&E has been working with Supreme Cores, another Milwaukee-based company, to provide the foundry with high quality sand cores.

Read Entire ArticleCASE STUDY: A SINGLE PART MAKES BIG IMPACT FOR PULP PROCESSOR

Discover how Axton's partnership with SF&E revolutionized pulp processing equipment, introducing a segmented ADI 600 screw for heightened efficiency and reduced downtime. Through meticulous design and material selection, this innovative solution showcases the power of collaboration in optimizing industrial operations.

Read Entire ArticleStreamlining Investment Castings: The Waterblast Advantage

One of the important steps for producing investment castings involves removing the investment casting shells. Stainless Foundry & Engineering (SF&E) recently replaced a manual process using a knockout hammer, spinner blast, and a hand chisel with the automation of a high-pressure waterblast.…

Read Entire ArticleConval Case Study: From Out of a Bind to Prepping for Growth

Conval Inc., is a global leader in high-performance valves for the world’s most demanding applications. For Conval, high temperature means a ball valve that can withstand 1200 degrees F. High pressure means handling 2,000 psi pressure with ease. Rigorous standards are in place for the quality, durability, and delivery time of Conval valves because facilities like power plants depend on them for steam, hot water, and chemical applications.…

Read Entire ArticlePHOTO STORY: MILITARY PARTS

All major weapons systems, ground transport, naval vessels, and military aircraft contain metal castings. These photos demonstrate the breadth and depth of SF&E’s experience serving OEMs in the military industry.

Read Entire ArticleFueling the Future with Precision Nuclear Power Components

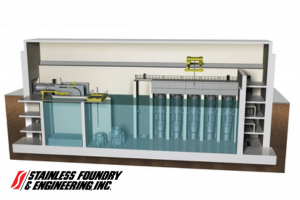

As the nuclear industry continues to grow, we take quality to the next level with non-destructive testing (NDT), comprehensive procedures, personnel qualifications and certifications. Check out the full article for visual insight into the attention to detail the SF&E team applies to keep nuclear plants safe.

Read Entire ArticleReady for the Future of Nuclear

Nuclear is getting a fresh look. Between the clean energy benefits, the development of small modular reactors, and the U.S. Navy's continued reliance on nuclear-powered aircraft carriers and submarines, the industry is growing. SF&E has produced nuclear parts for nearly as long as the industry has been around. Check out our plans to see how we will continue to serve the industry at large!

Read Entire ArticleMorgan Joins Stainless Foundry & Engineering Sales Team

Stainless Foundry & Engineering (SF&E) today announced that Mr. Kim Morgan has joined the company as a Sales Consultant. In this role, Mr. Morgan will promote the foundry’s capabilities to manufacturers located in the U.S. and Canada.

Read Entire ArticleBuilding on Brass and Bronze

The need for brass and bronze castings continues to grow in critical industries including NAVSEA, oil and gas, mining, construction, and food and beverage. Brass and bronze are non-ferrous metals that have highly-corrosion-resistant properties, making them ideal for parts submerged in seawater and pumps that move abrasive slurries.

Read Entire ArticleThe A Team: Introducing a New Alloy Requires Inter-Departmental Process and Skill

Stainless Foundry & Engineering (SF&E) has built an impressive offering of 250 ferrous and non-ferrous alloys. SF&E takes a methodical approach that involves all departments. Each department contributes to delivering castings using new alloys.

Read Entire ArticleSummer 2023 Interns

SF&E takes pride in being able to work with students and provide them with opportunities to grow within our company. In fact, many interns at SF&E may be able to continue their time here as full-time employees.

Read Entire ArticleLose a Supplier, Gain a Partner

Tri-Tec Manufacturing is one of the country’s leading FireSeal Ventilation Valve Closure manufacturers, a vital component of the first line of safety for the US Navy’s fleet. They take seriously their mission to provide innovative and affordable solutions for our Nation’s defense.…

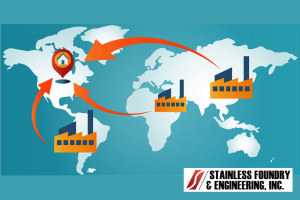

Read Entire ArticleHomecoming- The Keys to Rebuilding the Domestic Supply Chain

A dramatic shift is happening in American manufacturing. This transition involves a growing number of companies reversing a six-decade trend by moving some or all their production from overseas to the United States. While this reshoring effort bodes positive change for the companies and the country, companies will need to build new supplier relationships to make this change work successfully.…

Read Entire ArticleReady for Service – How Stainless Foundry and Engineering Measures up to NAVSEA

Whether it is the military or a commercial customer, the SF&E team is meticulous when it comes to writing and following production control plan procedures for efficient production and quality control. Learn about our elevated level of testing and inspection processes, the 12 external audits we completed in the last 2 years, and how we train – and re-train – to remain compliant with high-spec work serving the US Navy.

Read Entire ArticleNon-Galling ILLIUM 8 Alloy Is the Right Recipe for Food Processing Equipment

Nickel-based ILLIUM 8 alloy has qualities that are ideal for food, dairy, and pharmaceutical processing equipment, as well as petrochemical equipment. We have been pouring ILLIUM alloys for decades, continuously working to improve our processes with every pour. Learn more about ILLIUM 8, and how its non-galling and corrosion-resistant qualities make it a critical component to the success of some of our most vital industries.

Read Entire ArticleClyde Union® Pumps Keep The Oil Flowing On Offshore Drilling Platform

One of the most rugged workplaces in the world is located nearly 200 miles off the Newfoundland coast on the Hibernia oil production platform. To ensure the oil keeps flowing, Stainless Foundry and Engineering recently worked with the pump manufacturer Clyde Union Canada Ltd., to upgrade the platform's three centrifugal pumps.

Read Entire ArticleSupporting the Global Defense Supply Chain

All major weapons systems contain a metal casting. Stainless Foundry & Engineering works with different alloys and techniques to produce castings that are better equipped to support the defense industry needs, anywhere from submarines to advanced weapons systems.

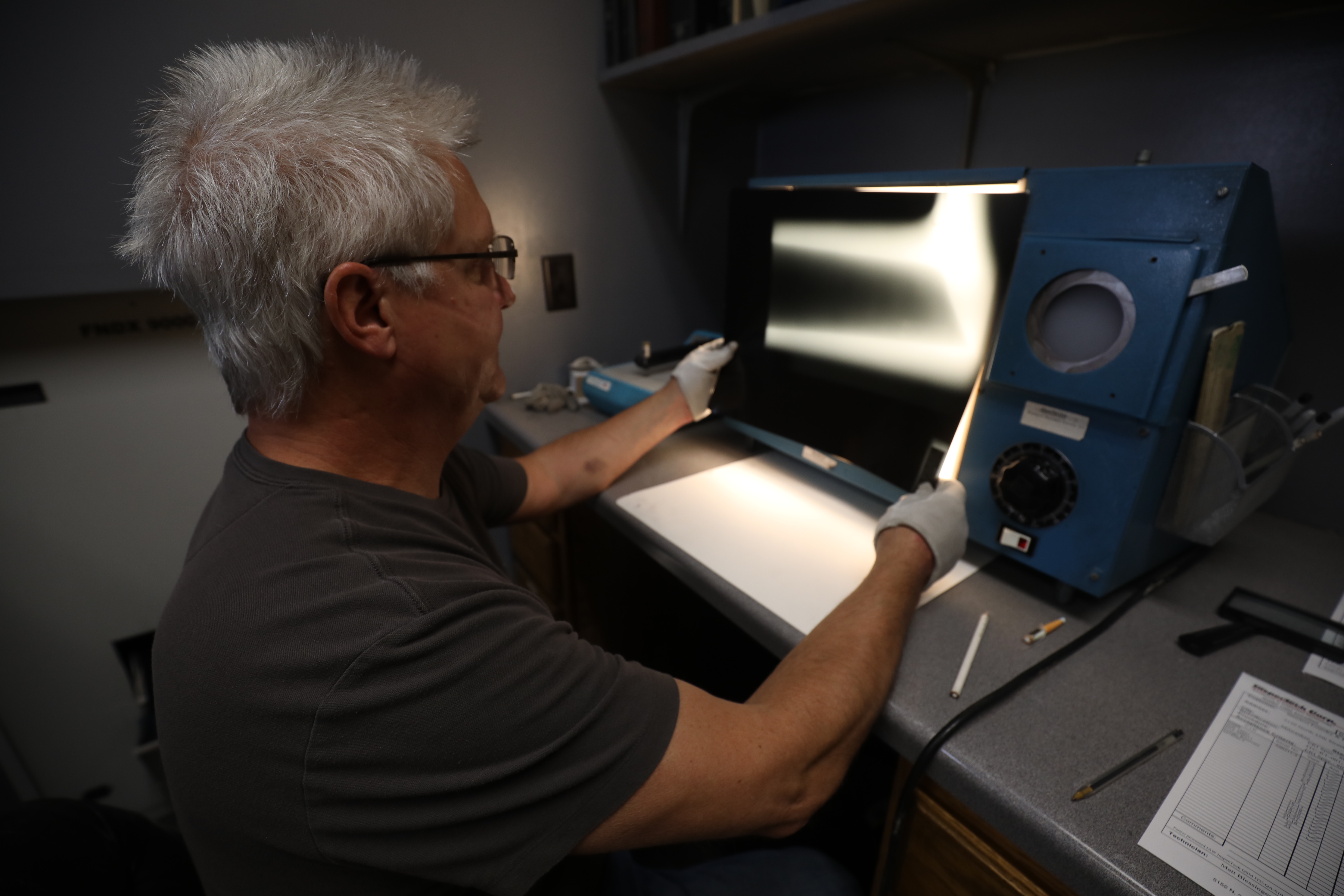

Read Entire ArticleHigh Spec Castings – What You Need to Know about Testing

Parts produced for the nuclear, petrochemical, power generation, military, and defense industries require a high level of specification. Thorough testing is imperative to ensure these critical castings not only meet customer and industry standards, but they have the structural integrity to perform throughout their expected service life. Here’s how we do it.

Read Entire ArticleAnatomy of a Pour: Investment Casting Photo Story

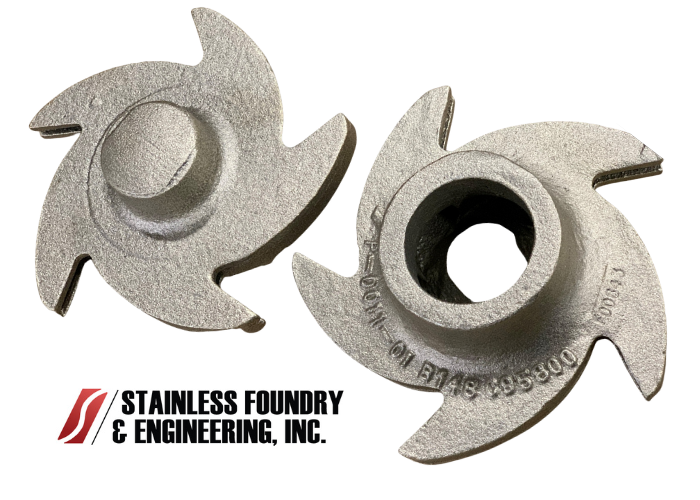

When Stainless Foundry & Engineering (SF&E) opened its doors in 1946, we specialized in sand casting, primarily producing impellers for pumps. SF&E added investment casting to its service offering in 1968 in response to the increasing demand for precision parts. We’ve documented our investment casting process in a series of photos as a way to pay homage to this practice, which dates back to 3,000 B.C.

Read Entire ArticleStainless Foundry & Engineering, Inc. Promotes McCaffery to Vice President

Mitch McCaffery has been promoted to Vice President of Sales & Marketing for Stainless Foundry & Engineering, Inc., a one-stop-shop foundry specializing in sand casting, investment casting, and machining.

Read Entire ArticleAnatomy of a Pour: Sand Casting Photo Story

Sand casting is a versatile and cost-effective technology that has been used for thousands of years. Nearly any part configuration can be created in metal as a sand casting. Stainless Foundry & Engineering (SF&E) has specialized in sand casting since we opened our doors in 1946. We’ve documented our process in a series of photos below as a way to pay homage to this time-honored practice.

Read Entire ArticleSF&E Partner InspecTech Corp. Brings Precision and Dependability to NDT

Non-Destructive Testing (NDT) is a vital part of the foundry process, especially for projects in nuclear and military industries. Stainless Foundry & Engineering (SF&E) partners with InspecTech Corp. onsite to deliver convenient, comprehensive, and efficient NDT, making SF&E a true hub for all casting, testing, and machining capabilities.

Read Entire ArticleHow to Get Ahead and Stay Ahead in Pumps & Valves

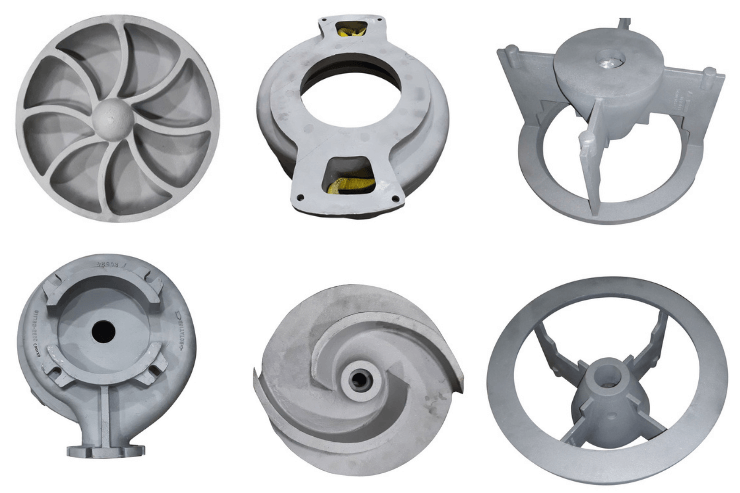

In the late 1960s, Stainless Foundry & Engineering (SF&E) was one of the top producers of impellers in North America. More than 50 years later, impellers remain our top produced part, along with other crucial pump and valve components. In honor of our Top 6 most produced parts, we’ve collected the Top 6 ways to get ahead and stay ahead in the foundry industry.

Read Entire ArticleTrends in Food & Beverage Pumps

As food processors work to meet consumer demand for product innovation – including healthy alternatives, fresh ingredients, novelty experiences, and global flavors – their equipment must be innovative as well. At the center of it all are pumps.

Read Entire ArticleReverse Engineering: SF&E Creates 3D Model from Pattern

3D Modeling has proven results for OEMs, especially when sourcing complex parts. Prior to 3D modeling technology, a full pour was done to determine the integrity of a sand or investment casting. Every time a non-compliant defect was found, the rigging and gating needed to be modified and the process started all over again. This cost the customer and foundry valuable time and money.

Read Entire ArticleFoundry Expert Vijay Talwar Joins Stainless Foundry & Engineering as Director of Metallurgy & Process Engineering

Stainless Foundry & Engineering (SF&E) is pleased to announce the addition of Vijay Talwar as Director of Metallurgy & Process Engineering. Talwar brings with him over 40 years of foundry experience with significant knowledge in process engineering, metallurgy, alloy development, and the markets SF&E does business in.

Read Entire ArticleOil Refinery Partners with Turbonetics and Stainless Foundry & Engineering on Illium PD Double Suction Casing

Stainless Foundry & Engineering (SF&E) helps its customers solve application challenges by focusing on quality engineering, field testing, and the proper alloy mix for the industry served. Turbonetics Engineering & Services finds trust and reliability in SF&E's process. Read more about how this partnership has grown to support Turbonetic's pump needs.

Read Entire ArticleCore Parts: Anatomy of a Centrifugal Pump

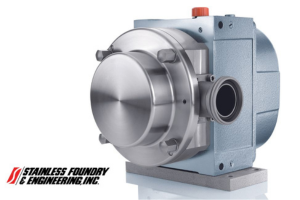

Stainless Foundry & Engineering was established more than 75 years ago with a focus on closed impellers for pumps and other parts that were difficult to cast. While we have expanded and developed our scope of expertise and service offerings, pump parts continue to be one of our strengths. In the following, we break down the anatomy of a centrifugal pump - an equipment staple for oil and gas, food and beverage, chemical and other such industries.

Read Entire ArticleFor Fristam Pumps, Mutual Trust is Key to 20+ Year SF&E Partnership

When you walk through a grocery store, anything that is contained in a bottle, can, or tube most likely utilized a pump in the production process. From the milk processor removing milk from a tanker truck to the toothpaste manufacturer filling tubes, pumps make it all possible.

Read Entire ArticleState of the Industry: How Foundries Plan to Weather 2022

Foundries are facing the same challenges that most businesses are facing this year: limited workforce, parts scarcity, and shipping bottlenecks. It is both unprecedented and familiar at the same time. For years, foundries have had to remain flexible as order volumes increase and decrease in sync with the price of raw materials.…

Read Entire Article4 Critical Questions to Ask Before Moving an Alloy to a New Foundry

Starting a new relationship with a foundry is more than an investment in time and money to get patterns and tools over to them. The new foundry partner will also have to match your alloy specifications, which can feel like starting from scratch between your engineering team and their metallurgists.

Read Entire ArticleSpotlight on Quality & Engineering – a 75-year Evolution at SF&E

Stainless Foundry & Engineering (SF&E) has “engineering” in the name because we aren’t just a particularly focused alloy foundry, we produce over 250 different ferrous & non-ferrous alloys. Metallurgy has always been a strong focus that enables us to create solutions for our customers.

Read Entire Article75 Year Proclamation from Milwaukee County Executive

Milwaukee County Executive David Crowley paid a visit to Stainless Foundry & Engineering on Wednesday, December 15th to award a Proclamation to SF&E for achieving 75 years. After growing up in the neighborhood, Crowley shared his excitement for finally being able to see what Stainless Foundry & Engineering was all about.

Read Entire ArticleStainless Foundry Celebrates 75 Years of High Quality and Dependable Service

“When I was young, my father told me something I will never forget. He employed 100 people at Stainless Foundry at the time, and said to me, ‘We don’t have 100 people working with us, we have 100 families who depend on Stainless Foundry for their livelihood.’

Read Entire ArticleStrohwig and Stainless Prove Supplier Partnerships Are a Two-Way Street

Strohwig Industries has been an approved supplier for Stainless Foundry & Engineering for years, but in the past three, our relationship has expanded into a preferred partnership. Strohwig specializes in complex, high-quality molds, dies, and precision parts.

Read Entire ArticleSF&E Flexes with High Chrome White Iron Complexity

When Stainless Foundry & Engineering (SF&E) announced its high chrome white iron alloy capabilities last year, the engineering team was focused on introducing processes and tools to continuously improve iron quality over time.

Read Entire ArticleHow a Short Domestic Supply Chain Saves on Long-Term Costs

It’s an age-old question for original equipment manufacturers (OEMs) – are the cost savings from offshore outsourcing worth the potential supply chain risk? Lower cost regions and countries can seem appealing from a profit margin standpoint.

Read Entire ArticleHigh Specification Inspection Cell Investment Creates 3 Key Benefits

The volume of high specification work at Stainless Foundry & Engineering (SF&E) has continuously increased. So much so, that high specification nondestructive testing (NDT) was creating a bottleneck in SF&E’s newly improved commercial production line, which prides itself on 4-6-week lead times.

Read Entire ArticleExpertise in Nuclear & NAVSEA

Stainless Foundry & Engineering (SF&E) has been producing cast and machined components for the nuclear and military industries for over 70 years. Our foundry and technical engineering staff have expertise in sea, land, and air applications.

Read Entire ArticleCan Your Foundry Weld This? SF&E Can.

Stainless Foundry & Engineering, Inc. (SF&E) casts over 250 alloys. When pouring that many materials, from time to time, we are required to perform repair welds to remove surface casting defects.

Read Entire ArticleCASE STUDY: Partnership Streamlines Production for Hydro-Thermal

Production can only be as smooth as a facility’s material flow. For Hydro-Thermal, the global leader in the development and manufacturing of Hydroheaters, production cannot be interrupted.

Read Entire ArticlePHOTO STORY: SF&E Machining

If you’re paying extra freight costs to ship castings from foundries to machine shops, or having quality struggles uncovering defects after machining, a foundry with in-house machining capabilities could be your solution.

Read Entire ArticleModern Casting Features SF&E Careful Customer Contract Review

In March 2021, American Foundry Society’s issue of Modern Casting highlighted the importance of careful customer contract review and quality engineering at Stainless Foundry & Engineering (SF&E).

Read Entire ArticleFirst-of-its-Kind Antimicrobial Stainless Steel

Advancing Medical Innovations (AMI) announced earlier this month that its client, Performance Compounds Inside (PCI), has made historic advancements in metallurgy with its 3PRE Technology, a novel and proprietary process of activating antimicrobial properties.

Read Entire ArticleSchutte & Koerting Chooses SF&E Bronze for Quality, Consistency

Schutte & Koerting (S&K) has more than a century of experience in the design and manufacture of steam jet vacuum systems, steam jet heaters, exhausters and compressors, scrubber systems, desuperheaters, thermocompressors, eductors and syphons, ejectors, and valves.

Read Entire ArticleBronze is Back – SF&E Dusts off 75 Years of Knowledge to Meet Growing Demand

When Stainless Foundry & Engineering opened its doors 75 years ago, bronze was one of our core competencies. SF&E worked with multiple military and commercial customers to pour non-ferrous propellers, various pump components, and split case pumps, among other parts.

Read Entire ArticlePHOTO STORY: BRONZE ALLOYS

Stainless Foundry & Engineering (SF&E) has been producing cast brass and bronze alloys since the 1970s. Within the past year, we have ramped up volume production and equipment investments to meet a growing need.

Read Entire ArticleSF&E Improves Castability and Production Timeline for Complex Impeller

A Stainless Foundry & Engineering (SF&E) customer recently learned their former foundry partner’s impeller was failing in the field and needed to be replaced. Time – but more importantly, the ability for the OEM to make things right – were on the line.

Read Entire ArticleRestructured, Revitalized, Re-Invigorated

Stainless Foundry & Engineering’s (SF&E) President & CEO, Jim Stachowiak, sat down with Manufacturing in Focus Magazine to share the company’s latest news and updates about restructuring, the COVID-19 affects on the foundry, the future of manufacturing, and more.

Read Entire ArticleIs Your Foundry Partner Adhering to Governmental Purchasing Requirements?

To function in the modern, industrialized manufacturing environment, business and quality systems require controls with formal guidelines and good practices. This is especially true when working in government purchasing.

Read Entire ArticleNon-destructive Testing Usages in the Foundry

Stainless Foundry & Engineering (SF&E) is nearing the end of a multi-phase, multi-year operations throughput improvement project. The goal: maximum optimization for an above-and-beyond customer experience.

Read Entire ArticleThe Anatomy of a Pour: SF&E Takes on High-Chrome Iron Casting

Stainless Foundry & Engineering (SF&E) is nearing the end of a multi-phase, multi-year operations throughput improvement project. The goal: maximum optimization for an above-and-beyond customer experience.

Read Entire ArticleShrinkage and Gas. How to Eliminate These Common Casting Defects

When castings have openings, cavities, porous sections, and similar defects on the internal or external surface, it is often called porosity. It is generally due to shrinkage or gas as the casting cools. Both are caused by very different sources.

Read Entire ArticleHow SF&E is Cutting Lead Times – Again.

In 2019, Stainless Foundry & Engineering announced that halfway through its multi-year initiative to overhaul sand and investment foundry operations, we had already achieved lead times between 5 and 7 weeks.

Read Entire ArticleSteel Founders’ Society of America Recognizes Robert Uitz as Master Founder

Robert (Bob) Uitz, Quality Assurance Welding Program Coordinator at Stainless Foundry & Engineering (SF&E), has been recognized by the Steel Founders’ Society of America as a Master Founder and the newest member of the Steel Founders’ Society of America Guild.

Read Entire ArticleWorth the Risk? 4 Critical Questions to Ask Before Working with a New Foundry.

There are many reasons why original equipment manufacturers (OEMs) question their relationship with an existing foundry partner, from inconsistent quality to ineffective communication.

Read Entire ArticleBusiness Update to Our Customers and Business Partners amid COVID-19

Dear Valued Customer, Future Customer, and Business Partner, Stainless Foundry & Engineering, Inc. has been operating daily and responding to all customer requests in a timely manner, pouring & delivering successful complex castings, in over 250 alloys, in record lead times.

Read Entire ArticleSF&E Pours Largest Nuclear Impeller in its History

We poured the largest impeller in the history of our company. Utilizing AOD ingot, we melted and cast 6,000 pounds of CA6NM martensitic stainless steel. The reputation of Stainless Foundry & Engineering (SF&E) was built on being an industry leader in manufacturing all styles of impellers.

Read Entire ArticleHow a Short Supply Chain Saves on Long-term Costs

It’s an age-old question for original equipment manufacturers (OEMs) – are the cost savings from offshore outsourcing worth the potential supply chain risk? Lower cost regions and countries can seem appealing from a profit margin standpoint.

Read Entire ArticleCOVID-19 – Update from our President & CEO

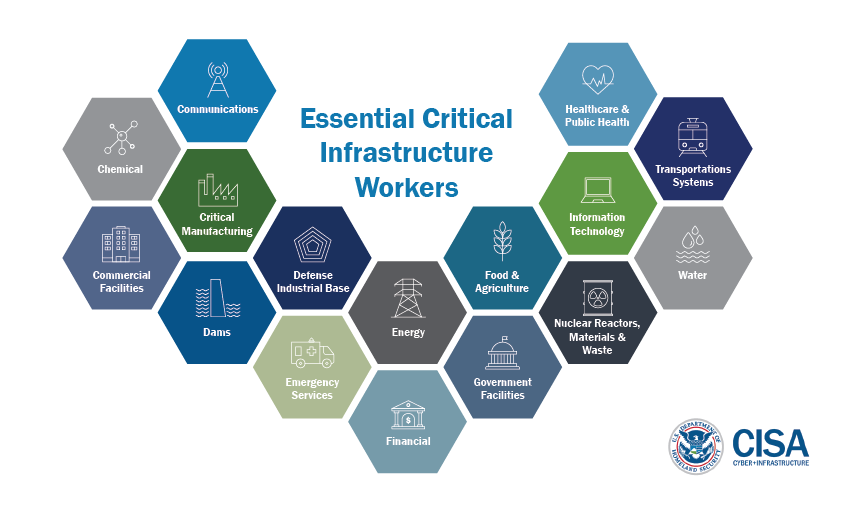

As we all come together to slow the spread of COVID-19 while keeping critical business operating, we want to share with all our Customers, Business, and Community Partners that Stainless Foundry & Engineering, Inc. has been deemed an essential business according to the U.S. Department of Homeland

Read Entire ArticleInvestment Casting Vs Sand Casting: Differences and Advantages

Investment casting and sand casting are reliable, cost-effective, quality manufacturing processes that allow for flexibility in budgets, timelines, and design.

Read Entire ArticleWhy Responsiveness is an Industry Game-Changer

If you asked a Stainless Foundry & Engineering (SF&E) customer six years ago about the company’s responsiveness, they might have said it was minimal. Or, more likely, they would have said it was “as expected.” Metal manufacturers have historically operated under the reputation that customers get what they get when they get it.…

Read Entire ArticleCan Castings be Welded?

The world of fusion welding has effected many industries and fabrication opportunities worldwide. Countless industrial items are assembled using a vast number of different welding techniques governed by numerous rules, codes and norms. Casting upgrade welding is a very specialised series of operations.…

Read Entire Article“Going above and beyond to reduce cost”- a Gen Z view

Anthony Geiger, Foundry Engineer at Stainless Foundry & Engineering, Inc., is part of the up and coming generation of enthusiastic young metalcasters who will take the industry into the future. He has worked for Stainless Foundry since mid-2018. When you ask him if he likes his job at Stainless Foundry in Milwaukee, he says “I love my job.”…

Read Entire ArticleThree Competitive Advantages to Inventory Stocking

Inventory stocking is a great opportunity for manufacturers to smooth the transition between customer order entry and shipping. Any chance to improve the customer experience will increase the chances the customer stays with you for the long-term.

Manufacturers often stock their own inventory on site.…

Read Entire ArticleWhen to Convert Costly Fabrications into Castings

Do your fabricated parts consist of multiple components that need to be cut or machined to size and go through weld fabricating before being machined as one? If so, your parts might be an ideal candidate for a casting.

Read Entire Article